Choosing the right PCB assembly fabrication solution for your electronics business is a crucial step in creating a successful electronic product. Without a high-quality circuit board, the reliability, efficiency, and even safety of your devices could be compromised. “Quality” can mean a wide range of different things to different companies, but it essentially says that the manufacturing of the PCB assembly aligns to the exact specifications of the PCBA documentation with absolutely no errors. To accomplish this goal, finding the appropriate fabricator is essential. Once you have a quality raw board, PCB assembly becomes a lot more simple.

The composition of a PCB

Before diving into the specific fabrication processes of PCBs, it’s important to know a few basics about the composition of a printed circuit board. Each board is made up of layers. There’s the substrate, or base material, which is often made with FR4 fiberglass. Next is the copper which can have one or more layers and vary in thickness. The copper conducts signals once PCB assembly is complete. Then there is solder mask which is designed to insulate the parts of the copper not meant to make contact with components in PCB assembly. Finally, the silkscreen is where numbers, symbols, and other indicators help humans working on the board during and after PCB assembly.

When deciding which type of printed circuit board is right for your PCB assembly fabrication project, it’s important to know some of the common language used in electronics manufacturing. Here are some terms you should be aware of:

Drill hit

This is where holes are drilled on your board. They should match your design exactly.

Pad

Components are soldered to this portion of exposed metal on the board.

Plane

Sometimes called a pour, this is a continuous block of copper defined by borders.

Reflow

Joints are created between pads using solder.

Slot

This is any hole in the PCB that’s not round. They may or may not be plated.

Surface mount

These mounts allow components to set on the board without leads needing to pass through it. Surface mount technology is widespread in modern printed circuit board manufacturing.

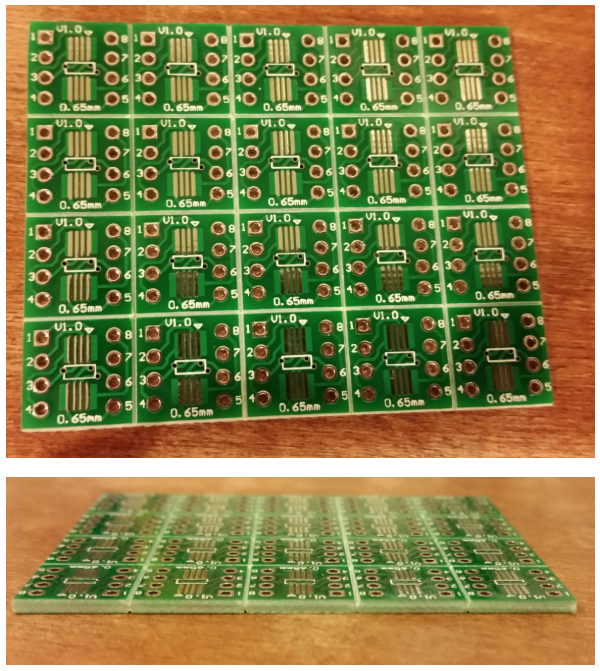

V-score

This partial cut through the board allows for splitting circuit boards into smaller pieces for multiple PCB assembly pieces.

V-score of printed circuit board.

Fabrication Methods

There are several different PCB assembly fabrication methods currently used in the electronics industry. Which one is right for your particular PCB assembly project will depend on a variety of factors. All fabrication methods require accurate and detailed designs to be effective. Some of the current fabrication options include:

Etching

This is one of the most common fabrication methods because it is easy and cost-effective. Chemical solutions, such as ferric chloride or ammonium persulphate, are used to remove unwanted areas of copper from the board.

Manual

The pattern design for a PCB can be manually drawn onto the board. A manual design is usually done with resist tapes or specialty pens.

Photographic

In this method, a drawing consists of photoresist material where ultraviolet light is projected onto the board. Then the cured board is submerged into a developer path, removing the affected material.

Direct etch

Laser printer toner uses a large quantity of pulverized plastic, meaning it can effectively be used to make a direct etch resist. A design is printed out on a laser printer and then ironed on to a circuit board blank.

Silkscreen

Usually reserved for the largest PCB manufacturers, silkscreen production involves photosensitive material and uses some of the same processes as T-shirt production.

Once one of these steps of PCB assembly fabrication is complete, there are a few final processes to finish before a board goes off somewhere else for PCB assembly. There’s cleaning, tin plating, drilling, cutting, through plating, and drawing the silkscreen legend. Sometimes PCB assembly happens where the raw boards are made, but most PCB assembly will occur at a different location.

Printed circuit board silkscreen. Altzone [CC BY-SA 3.0], from Wikimedia Commons

Choosing a PCB Manufacturer

Once you know what your specific PCB assembly demands are, it’s time to find a manufacturer that can meet them. You’ll want to see a careful balance between quality and cost. You’ll also want to find a source that can satisfy your deadlines. Manufacturing boards can take some time, but a good producer will be able to meet your deadlines so that you can proceed with PCB assembly fabrication on time.

Materials sourcing will also be an important factor when choosing a circuit board manufacturer. Companies that are always looking for the lowest cost materials will often suffer when it comes to quality, sabotaging your PCB assembly. They may also randomly switch suppliers; meaning boards will be of varying quality. Manufacturers should always follow regulations that affect hazardous materials and restrictions on conflict supply chains. Be sure to ask your electronic manufacturer questions about their certifications and equipment. Versa Electronics has experience with a broad range of fabrication houses that can meet all types of business, time, and expense factors. Contact a Versa representative to get started.